This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

Research and Development

This page introduces the Laboratory located in Shiogama, Miyagi Prefecture, which is a unique research institute owned by Kyokuyo.

The laboratory also features a product development plant, which enables integrated product development.

Role

We conduct product development, improvement, and analysis to ensure that we can provide food with safety and security in order to earn customer satisfaction and trust, based on our corporate philosophy of "Aiming to grow together with society, contributing to a healthy and happy lifestyle and food culture based on management of human respect."

Description of Business

Development of new product manufacturing processes, renewal of existing products, guidance for improving processes, production management, and analysis, etc.

Development

The laboratory develops new products, improves existing products, develops manufacturing processes, and assists the adoption of processing technologies at plants, based on requirements from the Product Development Department, Sales Department, and Manufacturing Department at Kyokuyo Co., Ltd. The on-site product development plant is utilized for researching processes for mass production, etc.

Production Management

In order to stabilize production and quality, the laboratory creates and manages manufacturing manuals for the products produced at each plant, and provides advice on stabilizing quality and optimal production methods.

Analysis

In order to support the supply and sale of safe and secure products, the laboratory conducts various types of analysis such as nutritional information, freshness, color tone, breaking strength analysis and bacteria tests, evaluates the superiority of components, quality, and taste, checks the safety of product changes and deterioration in terms of sanitation, and determines methods for selling products.

The results of this analysis are also utilized in product development and the purchasing of raw materials in order to contribute to stabilizing production and quality.

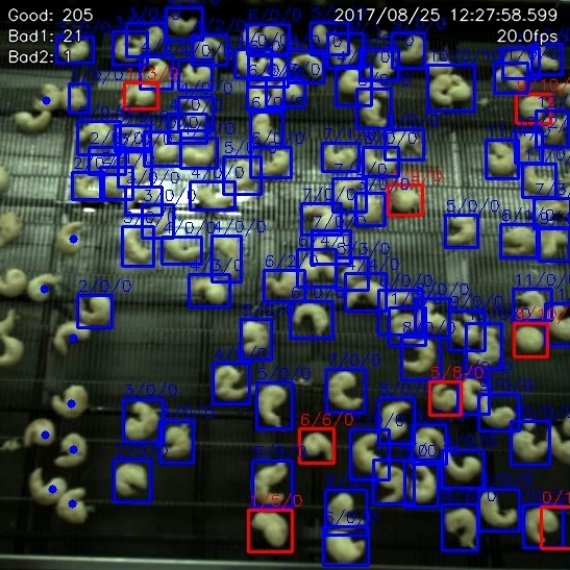

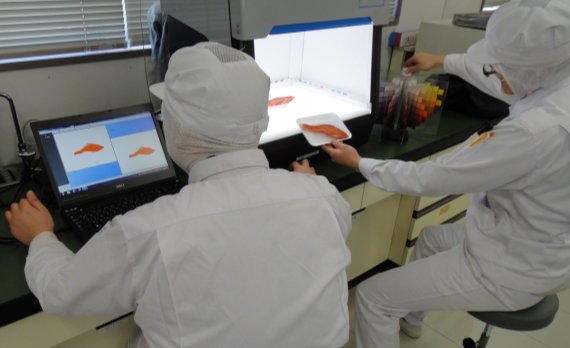

Demonstrating the Use of AI at Frozen Food Plant

Kyokuyo Co., Ltd. and Kyokuyo Shokuhin Co., Ltd. conducted a joint demonstration on the use of AI (artificial intelligence) to improve the efficiency of producing processed seafood products, in conjunction with NEC Solution Innovators, Ltd. and the Intelligent Information System research center at Tohoku University.

This demonstration used AI technology to diagnose camera images captured at the production lines for shrimp fritters, croquettes, and fried foods at the Shiogama Plant of Kyokuyo Shokuhin Co., Ltd. that produces frozen foods over a three month period from August to November 2017, in order to measure the production count and verify the precision of detecting second grade products.

Second grade products refer to products that do not meet quality standards, for example a shrimp fritter with excess or missing batter, or two shrimp stuck together.

Quality checks are normally performed visually by experienced technicians in the production process for processed seafood products, but a rapidly aging workforce and less workers in the seafood processing industry have led to major challenges, such as labor shortages and the need to pass down skills.

This demonstration was conducted as part of the technical development to replace the visual checks conducted by technicians.

Production count measurement achieved an accuracy of 99% or higher.

An accuracy of 99% or higher was achieved in the detection of second grade products by judging images captured at the production line at a rate of 0.05 seconds or less, and for some processed seafood products, we were able to check the possibility of connecting the cooking in the production process with the cause of second grade products.

The results obtained in this demonstration will be utilized to achieve a system that can be implemented in production processes.